Dr. Garikoitz Artola

“Innovation, built on the foundations of R&D aimed at improving industrial competitiveness, is part of our hallmark.”

Forming Technolgies

Forming Technologies research team focuses on the development of materials and processes for #Forging, #Rolling, #Stamping and #Additive manufacturing industries. Their research projects are aimed at improving the overall efficiency of the manufacturing process by working on the durability of #tools and manufacturing means, the optimization of #heat treatments or improving the understanding and knowledge on the behavior of materials, among many others.

Study of the corrosion behavior of CRA cladded high strength steel for offshore service

Components subjected to corrosion in the Oil & Gas sector are frequently manufactured in Corrosion

Rollover+: Anti-roll system for large vehicles

Weight lightening and safety improvement ROLLOVER + Lightened anti-rollover system for vehicles of great dimensions.

Simulation of hydrogen transport in ultra-high strength martensitic steels with zinc-nickel coating

-No information- Authors: A. Ravikumar (Helmholtz-Zentrum Hereon), C. Feiler (Helmholtz-Zentrum Hereon), D. Höche (Helmholtz-Zentrum Hereon),

SLIMDOWN – Method for weight reduction in structural components

WEIGHT LIGHTENING SLIMDOWN Development of lightened structural components Up to 20% weight loss Assured mechanical

SOFTCLAD – Manufacture of forming tools through the combination of LMD and cryogenic technologies

MANUFACTURING TOOLS Fabricación de herramientas de conformado mediante la combinación de tecnologías LMD y criogenia.

HSENSE – Real-time monitoring of the Hot Stamping process

manufacturing technologies HSENSE Real time quenching monitoring during steel hot stamping Patented technology Ensure the

Study of the corrosion resistance of powder mixture coatings carried out by means of LMD

This study is carried out with the objective of demonstrating the feasibility of using LMD

Influence of the Laser Deposited 316L Single Layers on Corrosion in Physiological Media

A multilayer laser-deposited lining of AISI 316L stainless steel makes a regular structural steel surface

Formability study of 2198 aluminium alloy for hot stamping

The aim of the present work is to assess the formability of the 2198 aluminum

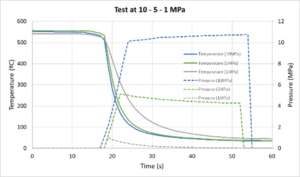

On the effect of testing setups on Aluminum alloys Interfacial Heat Transfer Coefficient Measurement

Sheet metal to die steel Interfacial Heat Transfer Coefficient (IHTC) is closely related to the

Evolution of hot stamping technology: a bibliometric review

Today’s huge automotive industry requires continuous innovations. In this sense, numerous publications on new materials

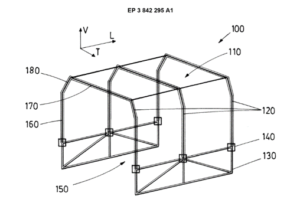

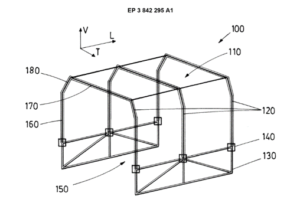

Rollover safety ring for vehicles

A rollover safety ring for a vehicle that defines a longitudinal axis (L), a vertical