Dr. Garikoitz Artola

“Innovation, built on the foundations of R&D aimed at improving industrial competitiveness, is part of our hallmark.”

Forming Technolgies

Forming Technologies research team focuses on the development of materials and processes for #Forging, #Rolling, #Stamping and #Additive manufacturing industries. Their research projects are aimed at improving the overall efficiency of the manufacturing process by working on the durability of #tools and manufacturing means, the optimization of #heat treatments or improving the understanding and knowledge on the behavior of materials, among many others.

A Preliminary Study on the Quality of Joining AISI 316 and AISI 3415 Steel by the Near Solidus Forming Process

In this study, the Near Solidus Forming (NSF) process, which falls under the umbrella of

Design evolution of Small Punch Test for Cryogenic Conditions

The study of mechanical properties in cryogenic conditions with traditional methods implies a large volume

Iron castings with improved corrosion and wear resistance by means of LMD coatings

Iron Foundry Iron castings with improved corrosion and wear resistance by means of LMD coatings

Method for producing a cast iron part with increased corrosion resistance and/or wear resistance, and the cast iron part obtained by said method

A method for producing a cast iron part comprising: a) obtaining a reactive paint comprising

New EoL Routes of Al-Li Aircraft Integral LBW and FSW Welded Panels including New Cr-Free Coatings

The end of fife (EoL) of new aircraft panels made of Al-Li alloys in which

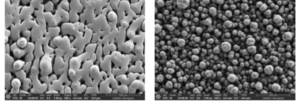

On the Mechanism of Formation of Bimodal Grain Structure in Al–4.5Mg–0.7Sc–0.3Zr Alloy Processed by Laser Powder Bed Fusion

Scalmalloy is an Al–Mg alloy with additions of Sc and Zr originally developed as a

Influence of the Zn-Ni coating on the 300M steel resistance estimated by Small Punch Testing

The main objective of the study is to confirm in which coating conditions it is

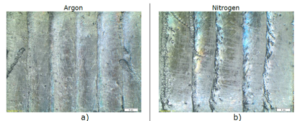

Influence of the shielding gas in laser metal deposition of AISI 316L

Shielding gases are a must in metal additive manufacturing. Consequently, their influence on the materials

L-DED numerical model for sensor embedding

Sensor integration is one of the drivers in modern industry for obtaining real-time data and

Development of dynamic crack growth tests on mooring steels for offshore applications

Vicinay Marine aims to improve their knowledge of the behavior of its steels under specific

Workshop: Secondary aluminum and steel

The recovery and reuse of metallic materials is a key area of work to improve

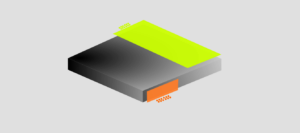

MANUFACTURING OF POWDERED MASTER ALLOYS

Advanced Materials and components POWDERED MASTER ALLOYS Manufacture of powdered master alloys to improve the