Dr. Garikoitz Artola

“Innovation, built on the foundations of R&D aimed at improving industrial competitiveness, is part of our hallmark.”

Forming Technolgies

Forming Technologies research team focuses on the development of materials and processes for #Forging, #Rolling, #Stamping and #Additive manufacturing industries. Their research projects are aimed at improving the overall efficiency of the manufacturing process by working on the durability of #tools and manufacturing means, the optimization of #heat treatments or improving the understanding and knowledge on the behavior of materials, among many others.

Report: “High quality recycled metals”

Metals are 100% recyclable and their reuse is a standard practice in the metal industry.

New high temperature resistant material for building hot-stamping rolling beam furnaces

The ROLLING BEAM furnace combines horizontal and vertical movements of beams to carry steel blanks

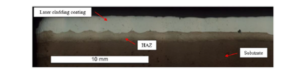

Method for preparing a stainless steel additive coating

The present invention refers to a method for obtaining a stainless steel additive coating by

TREAT- Optimization of Heat Treatments (methodology)

Sustainable manufacturing processes TREAT Efficient Heat Treatments Methodology for the development of optimized thermal treatments

Experimental design of tube steels characterization and validation test at cryogenic temperatures by means of Small Punch Test

Hydrogen is considered an energy vector, that is, a means to store and transport energy.

Small Punch Test on Jominy Bars for High-Throughput Characterization of Quenched and Tempered Steel

Studying the effect of quench and tempering heat treatments on steel, more specifically screening the

Ultrasonic Atomization and L-DED Application of a custom tool steel

The main goal of this work is to manufacture and test a custom L-DED powder

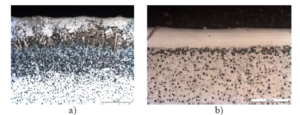

Metallic Powder Manufacture for Conditioning Cast Iron as an Additive Manufacturing Substrate

The main purpose of this work is to design and develop a metallic powder to

Hydrogen permeation testing parameter exploration for high-entropy alloys

Hydrogen permeation testing standards for metallic materials, such as ASTM G148 and ISO 17081, refer

ZnNi coating on UHSS for aeronautical applications: effect of base material and coating’s microstructure on the degassing process for preventing hydrogen embrittlement

Ultra-high strength steels (UHSS) are currently used in applications where high mechanical loads are required

Estimation of damage parameters for ductile fracture of Zn-Ni coated ultra-high strength 300M steel using a finite element model

Zinc-Nickel alloy coatings are being researched as a possible replacement for cadmium-based coatings because of

A Preliminary Study on the Quality of Joining AISI 316 and AISI 3415 Steel by the Near Solidus Forming Process

In this study, the Near Solidus Forming (NSF) process, which falls under the umbrella of