Dr. Garikoitz Artola

“Innovation, built on the foundations of R&D aimed at improving industrial competitiveness, is part of our hallmark.”

Forming Technolgies

Forming Technologies research team focuses on the development of materials and processes for #Forging, #Rolling, #Stamping and #Additive manufacturing industries. Their research projects are aimed at improving the overall efficiency of the manufacturing process by working on the durability of #tools and manufacturing means, the optimization of #heat treatments or improving the understanding and knowledge on the behavior of materials, among many others.

Influence of LP-DED speed (LMD vs EHLA) on corrosion behavior of single layer CRA overlays in marine environments

Corrosion Resistant Alloys (CRA) are high-cost materials but very useful in aggressive environments because of

MONOCOAT – protective cladding in a single layer

Advanced manufacturing MONOCOAT Anti-corrosion and anti-oxidation additive coatings on structural steel in a single clad

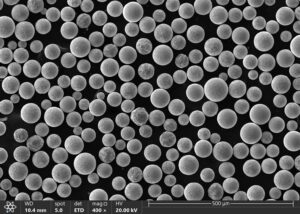

Atomized Ni-Ti powders for reactive paint

NEW MATERIALS Atomized Ni-Ti3 powder Ad-hoc metallic powders for developing protective surfaces. More information Promoting

Inconel 718 Hybrid Laser-Based Directed Energy Deposition and Wrought Component Characterization through Small Punch Test

The combination of wrought materials and laser-based directed energy deposition (DED-LB) is being increasingly used

Ad hoc development of metallic powders for the application of single-layer L-DED coatings

In recent years, L-DED (Laser Directed Energy Deposition) technology has become an interesting additive manufacturing

New strategies for refilling single-layer stainless steel on nodular cast iron

Con objetivo de mejorar la resistencia al desgaste y a la corrosión en las piezas

Ferrite-pearlite transformation time reduction strategy for the in-line heat treatment in restricted layout space forges

Hot forged steel parts frequently need to be submitted to a heat treatment after the

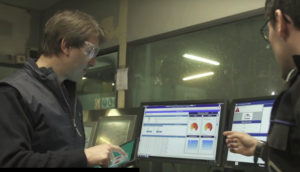

Intelligent Manufacturing Technologies

Field of specialization Intelligent Manufacturing Technologies We bring intelligence to metallic components development 4.0 industry

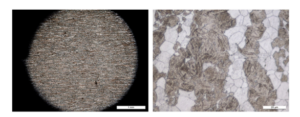

SPT Study of Spheroidal Graphite Degeneration in Cast Iron Components

In nodular cast iron Mg content is one of the main parameters to take into

HE:PROTECT – Advanced development of steel materials and components for application in underwater environments

service life improvement HE:PROTECT Advanced development of steel materials and components for acuatic environments. Reduce

Study of the degeneration of spheroidal graphite in cast iron components by means of Small Punch Test (SPT)

In the present study, an investigation is carried out in which the morphological changes of

Magnetic Materials

ADVANCED MATERIALS MAGNETIC MATERIALS Optimization of the magnetic properties of metallic materials for new technological