Dr. Garikoitz Artola

“Innovation, built on the foundations of R&D aimed at improving industrial competitiveness, is part of our hallmark.”

Forming Technolgies

Forming Technologies research team focuses on the development of materials and processes for #Forging, #Rolling, #Stamping and #Additive manufacturing industries. Their research projects are aimed at improving the overall efficiency of the manufacturing process by working on the durability of #tools and manufacturing means, the optimization of #heat treatments or improving the understanding and knowledge on the behavior of materials, among many others.

Improvement opportunities on fatigue and corrosion behaviors in offshore fastener threads combining a maraging steel skin with a class 10.9 32CRB4 core

The new generation of large offshore wind turbines (+15 MW) will require an improvement in

EFFICIENT HEAT TREATMENTS:

“Reduction of energy consumption by acting on austenization temperatures”

Decarbonization is a challenge for all energy-intensive industries. In heat treatment technology, production methods that

Study of the Hybridization of Ablation Casting and Laser Wire Metal Deposition for Aluminum Alloy 5356

The rapidly growing field of metal additive manufacturing (AM) has enabled the fabrication of near-net-shape

EFFICIENT HEAT TREATMENTS:

“Plating tool steels to reduce the carbon footprint of heat treatment”

Decarbonization is a challenge for all energy-intensive industries. In heat treatment technology, production methods that

Ni loss and phase structure formed during pulse laser powder bed fusion of Nitinol

In recent years, there has been a significant research effort in the laser powder bed

Diagnosis – BREF for the Smitheries and Foundries Industry

Sustainability and environment Smitheries and Foundry Industry BREF Diagnosis Do you know the positioning of

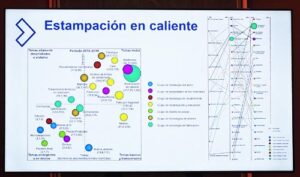

Decision-making predictive model development for the organization active positioning faced with the appearance of new technologies

We are now living in a world where the globalisation phenomenon has changed the world

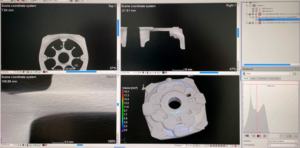

Advanced tomographic inspection for the development of new products and processes

Supporting Industry R&D Advanced tomographic inspection for the development of new products and processes Metrological

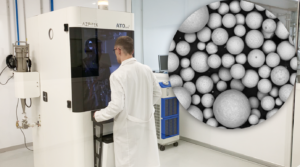

DEVELOPMENT OF METALLIC POWDER – Atomization of metallic powder

New materials Design and development of ad-hoc metallic powders Ultrasonic atomization of metal powders with

In-situ surface modification of high-silicon ductile cast iron produced by sand mold casting

Corrosion is a critical and common problem in cast iron castings used in industry. To

Keys and tools for Hydrogen Embrittlement minimization during ZnNi plating on Ultra High Strength Steels

Ultra-High Strength Steels (UHSS) are highly used in the aeronautic sector in critical components, like

Effect of Powder Reuse on Powder Characteristics and Properties of DED Laser Beam Metal Additive Manufacturing Process with Stellite® 21 and UNS S32750

In this work, the influence of powder reuse up to three times on directed energy