Dr. Asier Bakedano

“Developing lighter components and alloys at competitive costs is one of the main challenges we are embarked along with our clients.”

Light Materials

The Light Materials team develops new knowledge and technologies to optimize the manufacturing processes of components and structures made of these materials, as well as new alloys that open up new fields of application.

Efficient recycling of new generation aluminum alloys for the aviation industry.

The aviation industry is constantly evolving so that it can design lighter aircrafts, reduce consumption/emissions

An innovative predictive system of metallurgical defect in iron castings, in real manufacturing time

En las empresas de fundición es habitual la utilización de herramientas de simulación numérica, con

Study of Strontium fading in Al-Si-Mg and Al-Si-Mg-Cu alloy by thermal analysis

The production of high quality parts for automotive and aircraft industries requires both improved melt

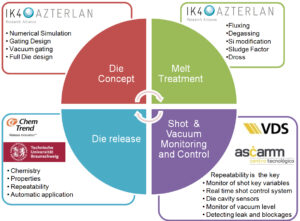

Need for high integrity light weight structural castings

Global warming and resource shortage have lead to an urgent demand for reducing the weight

Heat treatment optimisation of secondary AlSi10MnMg(Fe) test parts fabricated by vacuum assisted high pressure die casting technology

Primary AlSi10MnMg alloy is the most widely used alloy for manufacturig of vacuum assisted high

Effect of microstructure and casting defects on the mechanical properties of secondary AlSi10MnMg(Fe) test parts manufactured by vacuum assisted high pressure die casting technology

Primary AlSi10MnMg alloy is widely used for manufacturing of high ductility VPDC castings. This alloy

Method for obtaining improved mechanical properties in recycled aluminium casting free of platelet-shaped beta phases

The present invention relates to aluminium alloys, more particularly, it relates to aluminium alloy castings

Improved grain size prediction in aluminium-silicon alloys by thermal analysis

Grain refinement is a common practice in aluminium casting alloys, being Ti and/or B the

Microstructural features of primary and secondary ductile high pressure die casting alloys for the automotive industry

Primary AlSi10MnMg alloy is the most widely used alloy for manufacturing of vacuum assisted high

Effect of microalloying element addition on the microstructure, mechanical and corrosion behaviour of A356 secondary alloy with 0.30% Fe

This work investigated how trace additions of Mn, Cr and V affect the morphologies of

Interface characterization of aluminium casting reinforced steel inserts

During the last years, new technologies have been developed in order to reduce the environmental

Comparative Study of Different Interfaces of Steel inserts in Aluminium Castings

The necessity of preserving resources and to reduce environmental pollution makes light weight concepts highly