Dr. Asier Bakedano

“Developing lighter components and alloys at competitive costs is one of the main challenges we are embarked along with our clients.”

Light Materials

The Light Materials team develops new knowledge and technologies to optimize the manufacturing processes of components and structures made of these materials, as well as new alloys that open up new fields of application.

An innovative secondary aluminium AlSi10MnMg(Fe) for structural components with high ductility requirements

AlSi10MnMg primary aluminum alloy is widely used to manufacture structural components in the automotive market,

Industry 4.0 to optimize the HPDC process: how to monitorize and sensorize the HPDC cell

Undeniably, industry 4.0 revolution is reaching every industrial sector and the HPDC foundry could no

Rethinking sustainability of metallic alloys

Advanced metallic materials are complex materials with very different compositions. As they are integrated into

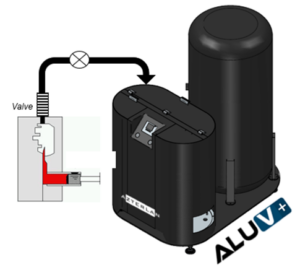

Vacuum pressure process and apparatus for high pressure die casting

A vacuum pressure process for high pressure die casting in a mould comprising a fixed

A Preliminary Study on the Quality of Joining AISI 316 and AISI 3415 Steel by the Near Solidus Forming Process

In this study, the Near Solidus Forming (NSF) process, which falls under the umbrella of

New EoL Routes of Al-Li Aircraft Integral LBW and FSW Welded Panels including New Cr-Free Coatings

The end of fife (EoL) of new aircraft panels made of Al-Li alloys in which

Embedded conductors in solidified molten metal for winding packs for high-field stellarators

The potential advantages of high-field stellarators are currently being recognised, as previously happened with tokamaks.

Friction Stir Weldability at High Welding Speed of Two Structural High Pressure Die Casting Aluminum Alloys

In this work, the friction stir weldability of two structural high-pressure die casting aluminum alloys

Industry 4.0 for aluminum foundry: an optimal management of the process to enhance competitiveness of the company

A standard HPDC industrial manufacturing process is likely to present the following characteristics: Equipment by

Porosity reduction in parts manufactured by means of High Pressure Die Casting (HPDC) technology

Die-casting is a widely used manufacturing process for the production of aluminum components. Among its

A sound vacuum system fully monitored to ensure the quality of the HPDC components

Gas porosity is an intrinsic feature of the HPDC process due to the fast metal

AZTERLAN at GIFA 2023

LIVE THE EXPERIENCE AT GIFA 2023 The AI driven IMMERSIVE FOUNDRY Meet us at Hall