Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

When is a Cast Iron Eutectic?

The literature often mentions that cast irons that appear eutectic by thermal analysis are hypereutectic

Study of the effect of commercial inoculants in high silicon cast iron components

High silicon alloys have experienced a significant growth in the last few years because of

Effect of the Type of Inoculant on the Shrinkage Porosity of High Silicon SG Iron

High-silicon spheroidal graphite (SG) irons present significant challenges to the production of sound castings as

Science behind KASANDRA®

This article shows the scientific foundations on which Kasandra® predictive software is based. Along with

Correction to: 90 years of thermal analysis as a control tool in the melting of cast iron

Since its first literature mention in conjunction with cast iron in 1931 by Esser and

Nodule Count, End of Solidification Cooling Rate, and Shrinkage Porosity Correlations in High Silicon Spheroidal Graphite Iron

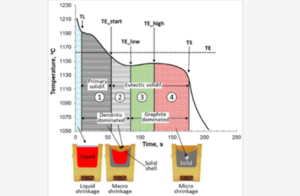

High-silicon spheroidal graphite (SG) irons present higher changes of density during the solidification process when

Quantitative Analysis of Solidification of Compacted Graphite Irons – A Modelling Approach

Several X-ray topography studies which have appeared recently in the literature show compacted graphite in

Method to determine the carbon equivalent content of a cast iron alloy having a hypereutectic composition and equipment to carry it out

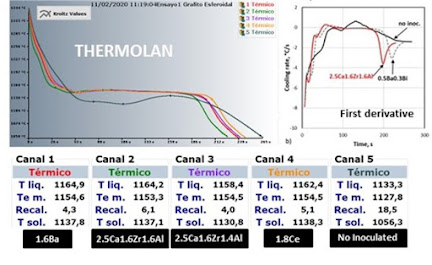

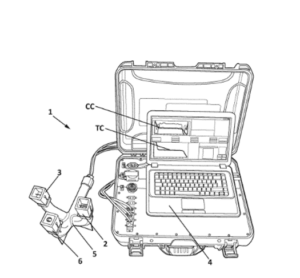

The invention relates to a methodology based on thermal analyisis to determine the carbon equivalent

Chunky Graphite in Low and High Silicon Spheroidal Graphite Cast Irons–Occurrence, Control and Effect on Mechanical Properties

Thermal analysis is largely used in cast-iron foundry shops as a means to check melt

Study of Graphite Nucleation in High Sulfur Ductile Irons

It is well known that sulfur is an excellent promoter of graphite and plays an

Determination of Microshrinkage Risk Index in Ductile Cast Iron Production

One recurrent problem in the foundry industry producing ductile iron castings for automotive industry is

Revisiting Thermal Analysis of Hypereutectic Spheroidal Graphite Cast Irons

This study deals with early solidification of hypereutectic cast irons at varying carbon content and