Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

Evolution of the manufacturing control and quality prediction system through thermal analysis

A common issue in foundry process is that with the same or very similar chemical

The effect of the substitution of Silicon by Aluminum on the properties of lamellar graphite iron

In cast iron, silicon and aluminum are elements that promote graphite precipitation and strengthen the

Al Gray Iron

NEW MATERIAL AL GRAY IRON Gray cast iron with improved mechanical properties. Greater resistance with

Industrial manufacturing of High Silicon castings

Manufacturing processes High silicon casting industrial manufacturing system. Assure a serial manufacturing without defects. More

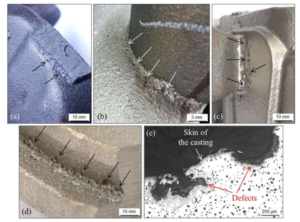

Casting Defects in Sand-Mold Cast Irons—An Illustrated Review with Emphasis on Spheroidal Graphite Cast Irons

Cast irons are known to be easy to shape by sand casting due to their

Tensile properties and fracture toughness at service temperatures of an optimized pearlitic ductile iron alloy for automotive crankshafts

Cast iron and forged steel have competed against each other for many years for different

Effect of the Magnesium Treatment on the Nucleation Potential of Ductile Iron

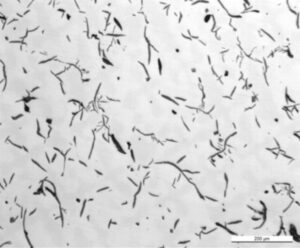

It is well known that the metallurgical quality and the nucleation potential of cast iron are influenced by a

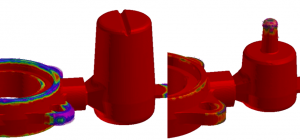

Optimized Riser 2D

New manufacturing technologies 2D Raiser Optimized raiser concept for a greater yield in horizontal foundry.

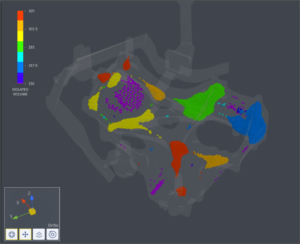

SALOMON – Multivariable process data analysis

Intelligent manufacturing SALOMON Multi-variable analysis system for manufacturing processes. Artificial Intelligence and cognitive systems applied

New generation of digital material for automotive components

With the application of Industry 4.0 technology, a new generation of advanced materials is developing

The Role of Selenium on the Formation of Spheroidal Graphite in Cast Iron

Sulfur, an element that belongs to group 16 (chalcogens) of the periodic table, is an

Influence of graphite morphology on the corrosion behaviour of cast irons for automotive industry

Cast irons are widely used in the automotive industry due to its excellent castability, fluidity,