Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

Mechanical properties optimization of as-cast ausferritic ductile iron as a function of section size and holding time

The ADI family shows the best resistance ductility relationship of the ductile iron materials due

ENGINEERED COOLING® – As-cast ausferritic materials by means of controlled cooling

New materials ENGINEERED COOLING® As-cast ausferritic materials without posterior heat treatments Patented technology More information

COLDMOLD – Accelerated cooling of large components

Manufacturing processes COLDMOLD® Accelerated cooling for large castings. Speed up your production process up to

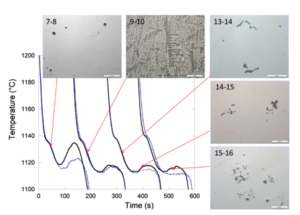

Application of Thermal Analysis to the metallurgical control of the casting process

Through these lines we will discuss the various functionalities of the thermal analysis tool Thermolan®

Effect of cobalt on the mechanical properties of high silicon spheroidal graphite castings

In order to optimize the mechanical properties of spheroidal graphite cast iron, different alloying elements

AZTERLAN at GIFA 2023

LIVE THE EXPERIENCE AT GIFA 2023 The AI driven IMMERSIVE FOUNDRY Meet us at Hall

Successive steps of growth of compacted graphite in cast irons

Holding during 8 hours a melt prepared for casting SGI leads to fading of the

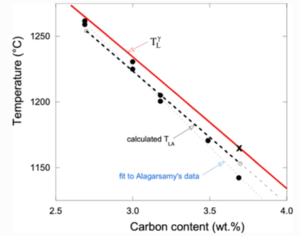

Is Thermal Analysis Able to Provide Carbon and Silicon Contents of Cast Irons?

The determination of silicon and carbon contents by thermal analysis is based on the recording

Guideline to improve machinability in ductile iron casting

open resource GUIDELINES FOR MACHINABILITY IMPROVEMENT IN DUCTILE IRON A helpful resource to address machnability

A Smart Digital Twin to Stabilize Return Sand Temperature without Using Coolers

In order to ensure the optimal state of recovered molding sand inside a foundry, it

Influence of the Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The final metallurgical quality of a ductile iron is determined by the components of the

New ductile cast iron digital grades for automotive components

This research paper demonstrate that new cast iron grade materials can be developed aided by