Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

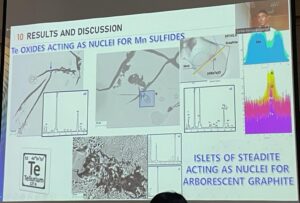

Metastable versus stable solidification of silicon cast irons, effects of magnesium and tellurium

Cast iron is a material with a unique combination of design flexibility, mechanical properties, wear

Green Molding Sands

In this manual, which is oriented to be an efficient tool in the hands of

New Approach to Develop Ductile Cast Iron Digital Grade for Automotive Components

This research work demonstrates that new cast iron materials can be developed aided by an

Density change upon solidification of silicon cast irons

Amongst the possible defects that can appear during casting, voids due to solidification shrinkage is

On the crystallography of the Mg–Si–Al nitride nuclei and of the graphite/nitride interface in spheroidal graphite iron

The role of Mg–Si–Al nitrides in the nucleation of low-sulfur spheroidal graphite Fe–C–Si alloys has

Utilization of steel slag as mold material for green molding castings to minimize silica dust in foundry process

The feasibility of black steel slag as mold material in sand casting, either as full

Mechanisms of Formation of Degenerated Graphite in Lamellar Graphite Cast Iron

The final morphology of graphite and its effect on the physical and mechanical properties of

Optimization of ductile iron casting production by using advanced thermal analysis and simulation techniques

The use of advanced techniques to control cast iron manufacturing processes lead to important reductions

Pseudo-passive films on cast irons: A strategy to mitigate corrosion by acting directly on microstructure

The effect of the microstructure on the corrosion resistance of four grades of cast irons

The Effects of Holding Time in the Heating/Pouring Unit on the Metallurgical Quality of Spheroidal Graphite Iron

The metallurgical quality of a ductile iron is determined by the components of the metallic

Compact graphite iron’s real time manufacturing control by thermal analysis

This research work presents a real time nodularity control methodology by thermal analysis for compact

A new approach of casting simulation tools integrated in the production line

The use of numerical simulation tools in the foundry is absolutely extended and it has