Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

Iron castings with improved corrosion and wear resistance by means of LMD coatings

Iron Foundry Iron castings with improved corrosion and wear resistance by means of LMD coatings

The mechanism of intermediate temperature embrittlement of cast irons by magnesium

Metallic alloys such as steels and nickel-based alloys are potentially vulnerable to high-temperature brittleness in

Kasandra®: Nucleation and solidification modelization of iron alloys for process control in real time

Nowadays, Foundry industries struggle to keep the competitiveness of their technology by means of more

SMART CASTING® – towards zero defect foundry

Manufacturing technologies SMART CASTING® Avoid finishing operations of low added value. Reduce operations, improve efficiency.

Embedded conductors in solidified molten metal for winding packs for high-field stellarators

The potential advantages of high-field stellarators are currently being recognised, as previously happened with tokamaks.

Evolution of the Metallurgical Quality of Spheroidal Graphite Iron during the Thermal Cycle of the Melt: Furnace – Ladle – Heating/Pouring Unit

The final properties of a ductile iron and its nucleation potential are determined by the

Damping behaviour of high silicon nodular cast iron

This work focused on producing and characterizing high silicon cast irons (microstructural analysis, tensile properties,

Intermediate temperature brittleness of a high-silicon spheroidal graphite cast iron

The target of this research work was characterizing high temperature mechanical properties of an as-cast

Method and additive composition for preparing ductile cast iron, and ductile cast iron obtainable by said method

The present invention relates to a method for preparing ductile cast iron, comprising the steps

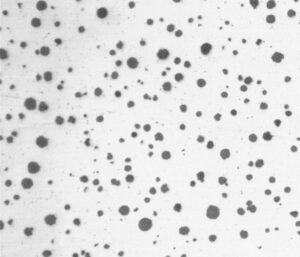

An adaptive approach to non-destructive evaluation (NDE) of cast irons containing precipitated graphite particles with the help of magnetoacoustic emission

Physical properties of cast irons strongly depend on both their microstructure and the presence of

An Objective Metallographic Analysis Approach Based on Advanced Image Processing Techniques

Metallographic analyses of nodular iron casting methods are based on visual comparisons according to measuring

Influence of the casting process on corrosion behaviour of 2024-T6 aluminium alloy in different conditions of pH and NaCl concentration

Corrosion behaviour of 2024-T6 castings produced by sand mould and metallic mould has been