Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

THERMOLAN® – Metallurgical quality prediction for iron casting

Iron Foundry THERMOLAN® Ensure the quality of your castings from the melt in less than

Artificial Intelligence Based Foundry Process Optimization Technology

The arrival of Industry 4.0 has stimulated a significant increase in the digitalization of foundry

SPT Study of Spheroidal Graphite Degeneration in Cast Iron Components

In nodular cast iron Mg content is one of the main parameters to take into

Prediction of the internal soundness of the castings directly on the production line. Importance of quality variations

The use of powerful computers has led to develop complex solidification simulation software that go

SMART YIELD – Solutions for a high yield foundry process

Iron Foundry SMART YIELD Produce more parts with the same amount of metal. Improve your

Study of the degeneration of spheroidal graphite in cast iron components by means of Small Punch Test (SPT)

In the present study, an investigation is carried out in which the morphological changes of

Report: “High quality recycled metals”

Metals are 100% recyclable and their reuse is a standard practice in the metal industry.

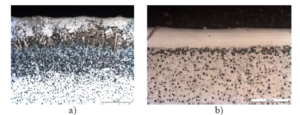

METALLURGICAL COMPENSATOR – Promoting graphitization in the last stages of solidification

New manufacturing technologies METALLURGICAL COMPESATIVE PRODUCT Promotes late graphitization to ensure the quality of ductile

Graphite Spheroids – The Way they Grow

Graphite spheroids are one of the most intriguing forms of aggregation of graphite. They can

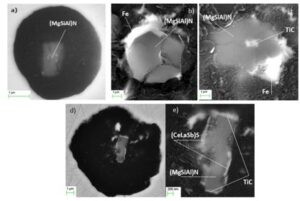

Graphite Spheroids – The Place where they are born

In the same way that a building needs a solid foundation to remain firm and

Metallic Powder Manufacture for Conditioning Cast Iron as an Additive Manufacturing Substrate

The main purpose of this work is to design and develop a metallic powder to

On the Role of Turbostratic Graphite in the Crystallization of Spheroidal Graphite During the Liquid-to-Solid Transformation

While turbostratic graphite is documented in many forms of graphite, there is a paucity of