Aitor Loizaga

“The optimization of foundry processess needs of a global vision of the process, where hundreds of correlated parameters affect the end result and the overall efficiency. However, any improvement process should be targeted by specific improvement objectives.”

Iron Foundry Technologies

The Iron Casting team develops #new materials, #control systems, technologies and processes that allow the manufacture of components with #enhanced properties and more #efficient industrial manufacturing processes. To this end, aspects such as: #metallurgical quality, #yield improvement, #savings in costs and raw materials, manufacturing technologies and #4.0 Industry or the #lead time of production and the feasability of new designs.

DIGITAL PASSPORT – Access to manufacturing data traceability of castings

Intelligent Manufacturing DIGITAL PASSPORT Part by part traceability of castings manufacuring process Multi-platform digital solution

New strategies for refilling single-layer stainless steel on nodular cast iron

Con objetivo de mejorar la resistencia al desgaste y a la corrosión en las piezas

Graphite in Cast Iron – From Carbon Atom to Graphite Spheroid

The momentous research efforts directed to the understanding of nucleation and subsequent crystallization of graphite,

Improvement of the Metallurgical Quality of Ductile Iron in Heating Pouring Units through Appropriate inoculation

The metallurgical quality of ductile iron is strongly affected by the nucleation potential of the

Effect of phosphorus on intermediate temperature embrittlement of high silicon

Spheroidal graphite cast irons can be susceptible to intermediate temperature embrittlement at temperatures between 350°C

SENTINEL® – Predictive control of manufacturing process by means of Artificial Intelligence

INTELLIGENT MANUFACTURING SENTINEL® Predictive control of the manufacturing process of metallic components. Ensure the efficiency

Improvement of the Wear Resistance and Particle Emissions of Hypereutectic Grey Cast Iron through Targeted Metallurgical Refinement

The control of automotive brake dust emissions released into the atmosphere has become a significant

PDManager®- Digitalization, traceability and storage of foundry process data

process data management PDManager® Digitalization, correlation, traceability and storage of the relevant castings manufacturing process

A CONTEMPORARY MONOGRAPH ON SILICON CAST IRONS MICROSTRUCTURE. From atom scale to casting.

This monograph finds its foundation in a simple fact: there is a paradigm with cast

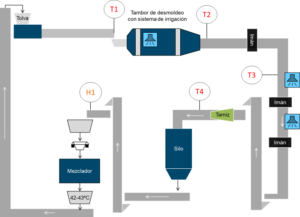

Intelligent water dosing system for conditioning the return sand

DIGITAL TWIN Intelligent water dosing system for return sand conditioning Ensure the optimal conditions for

Iron casting – Advanced training for Foundry Companies

Taught by iron casting technologies specialists from AZTERLAN, the Advanced Iron Casting Course reviews all

DyMetriCS® – Dynamic mold mismatch control

Intelligent manufacturing DyMetriCS® System to control the dynamic mismatch of vertical foundry molds Avoid finishing